People associate plastic with cheap disposal house wares or industrial use, but it doesn’t deserve this reputation. Plastic is a colorful, pliable, easy to craft material that you can employ for countless DIY projects. What’s even better, it is inexpensive and easily manufactured. Some of the most popular ideas are listed below.

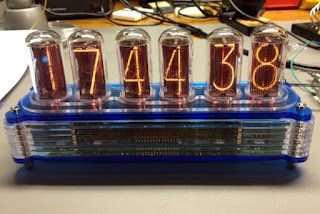

Acrylic is an excellent medium for any project as is it easily heated to become flexible. This allows it to be bent and molded. It also comes in an array of colors and finishes. Acrylic sheets can be custom made for any shape and size and are perfect for shelving and display cases. All you need to do is drill holes for the screws or other fasteners. You can add wood or other materials to create a unique look. It is also a great material for housing. Your favorite electronics, such as speakers and clocks, become interesting conversation pieces when placed in a transparent acrylic case. Acrylic works well with more creative projects also, like custom jewelry making, or LED signs and displays. It can be worked into ribbon shapes in vivid colors.

Polyvinyl chloride (PVC) is easy to find at your local hardware store in any length and in many diameter sizes. This plastic piping is perfect for anything requiring a round and strong material, like curtain rods or patio furniture. You can paint PVC to give it any look or style. It’s great material for the yard too, and you can use it for garden trellises, plant stakes, planters, vases, and fencing.

For bigger projects, fiberglass is a great choice, and is used for making the hulls on boats, and other parts on cars and airplanes. Fiberglass is a durable material and is easy to patch and repair. The process requires a concave mold to which the fiberglass is applied and allowed to cure for several days. You will either need a plug to fit the mold or a part you want to duplicate if you are designing the mold yourself, but it’s just as easy to find a specialty shop to do this part for you.

Plastic can be used in nearly any project where traditional materials are used, but plastic is generally less expensive and more durable. It is often surprising to see how visually appealing plastic can be. To find your inspiration, speak with a custom plastic company in Vista http://www.mgmplastics.com